Home > Products > Cooling Solutions > Under Floor Baffling

Computer Room Under Floor Baffling

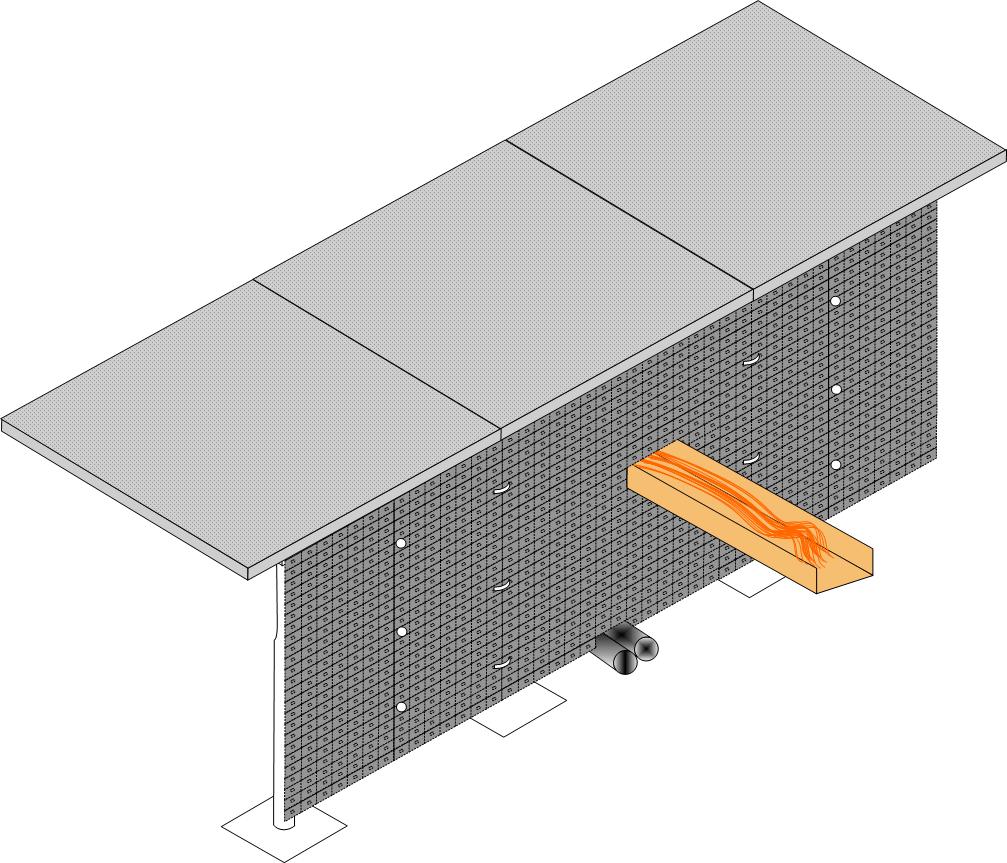

The PLENAFORM® Baffle System is scored both vertically and horizontally so sections can be removed or added onto to meet any height or width requirement. All angles of bend radius may be attained, including inside and outside mounting to raised floor pedestals. Continuous punch out hole pattern allows attachment to any style raised floor pedestal at any height or width location with cable ties. The baffles are die cut from a flame retardant polypropylene compound that is inert, non-conductive, and non-hygroscopic with a UL-VO 94 rating.

|

The PLENAFORM® Baffle System is a flexible, snap together, air flow baffle system which helps to solve dynamic thermal imbalances in data centre’s.

Add-on horizontal |

|

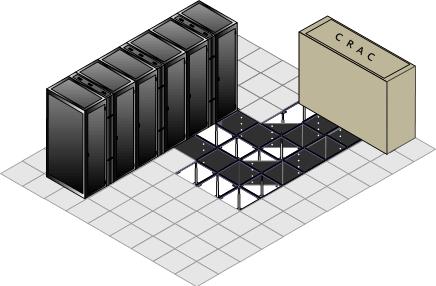

Easy InstallationThe PLENAFORM® Baffle System can be scored both vertically and horizontally so sections can be removed or added onto to meet any height or width requirement. All angles of bend radius may be attained, including inside and outside mounting to raised floor pedestals. Continuous punch out hole pattern allows attachment to any style raised floor pedestal at any height or width location with cable ties. The PLENAFORM® Baffle System is die-cut from a flame retardant polypropylene compound that is inert, non-conductive, and non-hygroscopic with a UL-VO 94 rating.

|

Many other uses:

|

|

|

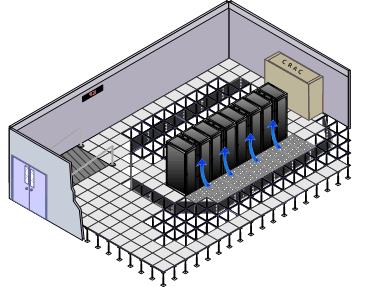

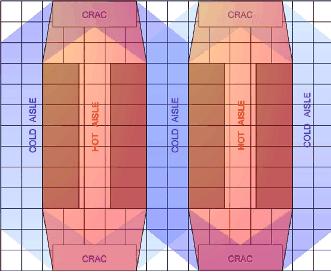

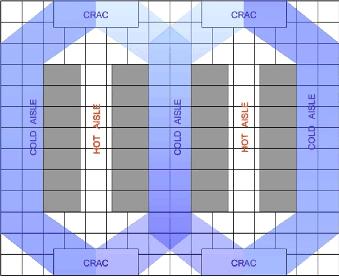

Creating dedicated “hot and cold aisles” or “rack and row” data centre equipment placement configurations with the PLENAFORM® Baffle System increases the static pressure delivering a higher volume of cooling through perforated tiles and at a further distance from the CRAC units.

The Venturi effect is attained and air pressure is increased in the dedicated cold aisles. By installing the PLENAFORM® Baffle System, air flow distribution may be directed more efficiently from the CRAC units for maximum equipment air cooling or air blocking requirements in a data centre raised floor plenum space. |

|

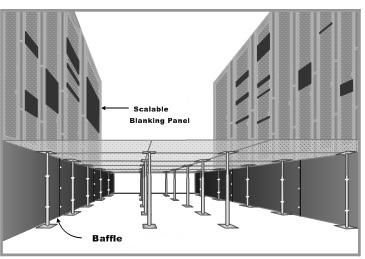

The PLENAFORM® Baffle System can also be installed in the ceiling plenum. Create dedicated return air paths in the ceiling plenum for more efficient heat return from the hot aisles to the CRAC unit intake heads.

You can even make CRAC extension intake heads with the baffles attached to a drop ceiling with removable clips.

|

The original intent of the raised floor to cool the mainframe environment has since become a raceway for cabling runways, copper, fiber and power distribution in addition to the air flow. Today's high density server farms, which are increasingly efficient heaters are requiring more power and cooling than ever before. The data centre evolution of an all air cooled environment has become a real challenge for facility managers to deal with these heat related issues, cooling inefficiencies and increased server densities. The challenge facility managers’ face is how to get the air that is beneath a raised the floor through the perforated tiles and into the front intakes of rack mounted vertically integrated server housings that are producing the heat. The PLENAFORM® Baffle System is a passive and contributory holistic solution that can be easily installed as an effective "VUF" or vertical under floor partitioning system, to direct air flow within the plenum space. The PLENAFORM® Baffle System direct the source of the cold air from the CRAC units to where the air is or is not needed. Velocity is the time rate of motion, therefore velocity pressure is the pressure caused by air in motion. When air from a CRAC unit is forced through a partitioned air flow space, static pressure is created. Without dedicated partitioning, as the air moves further away from a CRAC unit, the air velocity decreases. To maintain velocity pressure to particular 'hot zones' the PLENAFORM® Baffle System helps maintain the static pressure further away from a CRAC unit and is a simple solution to cool thermal hot spots in information technology equipment centre’s. It is of utmost importance for today's data centre facility manager and design engineers to develop a master plan when laying out equipment in relationship to the CRAC placements. The ideal objective should be to create un-obstructed dedicated air flow paths to the equipment. Open floor penetrations must also be sealed to manage air flow more effectively. Seal off unused space that does not require cold pressurised air flow. |

Easily cool a hot spot by routing air from the CRAC

Partitioning off perimeter corridors means more concentrated

|

Scenario 1Reduce energy consumption by partitioning off vacant data centre space with the baffles and turn off un-needed CRAC units. Lower your whole life costs. Example: A new data centre build-out only requires ½ of the data centre to be occupied by equipment over a 2 year growth cycle. Partitioning off unused space makes economic sense. "Installing the PLENAFORM® Baffle System under my raised floor to direct air to the required areas, I was able to shut down 5 of my 8 twenty ton air handlers. This saves my organization thousands of dollars a year in electricity and maintenance costs.” |

|

|

Scenario 2“By partitioning off two major corridors in our data centre with the PLENAFORM® Baffle System, we had increased cold air static pressure dedicated for our server racks. The increase in air pressure was measured at nearly 15%, and the temperatures were 10 degrees cooler at the tops of our server racks. |

Floor Height 30cm

"Surprisingly our CRAC unit #1 reduced it’s operation by 50% and CRAC unit # 2 by nearly 75%. Our servers are operating 5-7 degrees cooler than prior to the installation..."

Floor Height 60cm

"We partitioned off the unused space, were able to turn off 4 air conditioners and plus we have more concentrated air where our equipment is."

Floor Height 66cm

"Servers are operating about 6 degrees colder than prior to the installation."