Home > Products > Cable Brush Seals > In-Floor Cable Brush Seals

In-Floor Cable Brush Seals

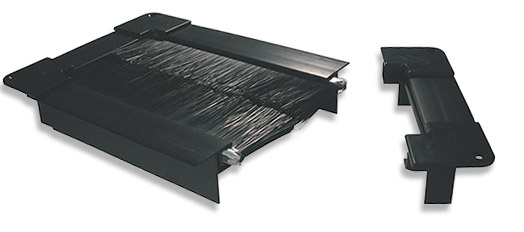

The in-floor seal is designed for installation in new or existing data centre raised floor tiles, with or without power or communication cables installed. For installations with cables in place, the end of the seal can be removed and placed around the existing cables in a pull apart design. Using polygonal filaments, our brush seal range provides the most effective seal to prevent the leakage of pressurised air around power and communications cables in floor cutouts.

|

|

For cutout holes with standard hole sizes:

Select the seal with a longer width closest to the cutout width. The side channels and brushes can be cut to length using a hand hack saw (the two side channels that hold the brush) and a bolt cutter for the brush. The brush and side pieces are easily re-assembled and the end pieces connected to the side channels. The seal is ready for cable installation.

The in-floor cable seal series can be installed in access holes ranging from 127 x 127 mm to 254 x 610 mm and for holes against an edge/wall the sizes range from 102mm x 305mm. For installations with cables in place, the end caps can be removed and placed around the existing cables. For smaller cutout sizes, use the Circle Seal (link here) series. For larger holes, ask your Over IP Group Sales Representative for a Seal solution. The unique design of the in-floor seal enables field modification permitting seals designed for longer width holes to be used in holes with the same depth but shorter width.

For cutout holes with shorter than standard length:

Select the seal with a longer width closest to the cutout width. The side channels and brushes can be cut to length using a hand hack saw (the two side channels that hold the brush) and a bolt cutter for the brush. The brush and side pieces are easily re-assembled and the end pieces connected to the side channels. The seal is ready for cable installation.

Construction:

Multi-piece black ABS plastic frame, high-quality nylon brush with Dyna-Seal technology

Hole Sizes:

127 x 127 mm to 254 x 610 mm / 5 x 5 in. to 10 x 24 in.

Installation:

No. 8 self drilling screws (supplied) or double-sided tape (not supplied)

Tile Cut Out Specifcations

Cutouts must be no less than the hole size specified for the seal model no. and no more than .125 in./ 3 mm larger in any dimension.

Seal Technology

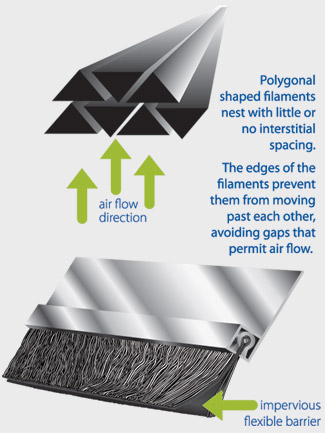

The brush seal is a patent pending technology that provides an effective seal between two areas of different dynamic pressures. The brush seals use polygonal-shaped filaments that nest and interlock to provide a more effective brush seal than brushes constructed with ordinary round filaments.

In addition, brushes have a solid sheet of thin, flexible material (membrane) sandwiched between layers of filament. The filaments hold the membrane in position to provide an additional, almost impenetrable barrier.

The edges of the filaments prevent them from moving past each other, avoiding gaps that permit air flow.

Save the Servers

The In-Floor Cable Seal consists of four corner pieces, four side rails and two, high-quality nylon brushes. The assembled seal can be mounted in the cutout prior to cables being run, or one end of the seal can be removed to allow the seal to be fit around existing cables.

The in-floor seal has built-in edge guards to shield the cables from the rough edges of the floor cut out.

For installations against a wall or other obstruction, the half in-floor sizes can be utilised.

The seal can be affixed to the floor using self-drilling screws (provided) or double-sided tape (not provided).

Using our patent pending Seal technology, the brush seal provides the most effective seal to prevent the leakage of pressurised air around power and communications cables in floor cutouts.

FAQ on Brushing

Have a question about installation, sizing, quality or something else? Click here

Installation

Installation on in-floor grommets Click here